In this article you’ll learn:

- What do you need to become a product design engineer?

- How much do product design engineers make?

- Product design engineer portfolio tips & examples

- What’s required of product design engineers at top tech companies: Apple, Google, Amazon

What is a product design engineer?

Product design engineers (PDE) utilize engineering science and design skills to build, test, and improve physical products (hardware) that satisfy end-users and are ready for manufacturing. Therefore, their designs must comply with established industry standards, be compatible with manufacturing technologies, align with business goals, and satisfy the user. PDE is the bridge between industrial design and manufacturing technologies.

The difference between product design and product design engineering

- Product designers (or industrial designers) are concerned with the product’s look, feel, and functionality based on user needs. They create sketches, renderings, or non-functional prototypes that are handed over to engineers.

- Product design engineers (or mechanical engineers) come up with the manufacturing aspect of the design, bringing it to life. They create 3D models, 2D technical drawings, and other deliverables used by machines to produce the product.

What do product design engineers do?

When not sitting in a meeting, product designers will be busy working on things such as:

- Conceptual design – using CAD (Computer-Aided Design) software to translate the product designer’s vision into something more tangible. They’ll also create 2D technical drawings for manufacturers.

- Prototyping/testing – PDEs create prototypes (eg.: with the help of 3D printers) to test their concepts and designs.

- Materials – it’s the product design engineers’ task to select and find suitable materials for their designs.

- Validation – after testing with prototypes, a few units of the product are actually manufactured for validation on three levels: engineering, design, and production. The validation process makes sure that the product works and looks the way it’s supposed to and is ready for mass production.

PDEs work on individual parts of a product

Most products are made up of smaller parts that make them work and look the way they are supposed to (eg.: in the case of a phone it’s the case, screen, cameras, buttons, circuits, chips, etc.).

During the early stages of the product development process, products are divided into sub-assemblies that are assigned to various engineers based on their expertise. Every engineer or team of engineers works on their specific part of the product and they also collaborate with others to make sure that the product functions as a whole.

How to become a product design engineer?

1. Earn a relevant BA degree

According to Zippia, 73,7% of product design engineers hold a bachelor’s degree and 11% also have a master’s degree. Unlike UX/UI design, this is one of those fields where having a degree is necessary to succeed. The most relevant university programs are mechanical engineering, industrial design, and applied mechanics.

2. Do an internship

Most product design engineering posts require a few years of experience in the field. The easiest way to fulfill this requirement is through an internship. An internship will give you valuable insights into the work life of a product design engineer.

The good news is that engineering interns are usually in-demand. However, if you have a specific, hip company in mind, you should keep an eye on their careers pages and prepare a strong internship application package, which should include a cover letter and a portfolio of your school projects

3. Specialize

Product designer engineers are usually specialized in a certain sub-field of mechanical engineering. The earlier you find your specialty, the easier it’ll be for you to find your ideal job.

If you can’t make up your mind, check the demand. Read job descriptions to find out what the companies you’d like to work with are looking for and start from there.

How much do product design engineers make?

The average product engineer base salary in the US is $94,876 per year. However, a lot depends on the location as well as your qualification and seniority level. So, the salary range goes from $69k to $129k per year.

In 2022, Amazon promises a $105,000/year base salary in their job description, while Google offers a range between $114,000-$173,000 based on role, level, and location.

Do you need a product design engineer portfolio?

Most product design engineer job descriptions don’t ask for a portfolio. However, during the hiring process, you might be required to submit samples of your past work. If you want to make a good impression, it’s best to assemble some of your past work into a presentable portfolio.

Product design engineer portfolio tips

Format

Most PDE portfolios are in PDF format, however, there are a few that are portfolio websites. Both formats are acceptable. However, websites have a few benefits over PDF files:

- They are easy to edit, especially if they were made with a visual website/portfolio builder like UXfolio.

- They are easy to expand with new projects and case studies.

- They can be accessed through a link. Recruiters won’t be forced to download a file to their computer.

Structure and template

Portfolio cover page

The first structural element of a PDE portfolio is a stunning cover page that sets the mood. Keep in mind that your portfolio tells a lot about your personality and taste. So make everything look professional but make it uniquely yours. We’ve seen both colorful and more serious, monochrome covers, so it’s really up to you.

Keep the contents of the cover page to a minimum. It should include only your title and a name. For example:

- Lydia Smith’s Portfolio

- Product Design Engineer Portfolio by Lydia Smith

Introduction/About

After the cover page, we’re usually welcomed with a short intro/about me section that reveals your back story: how and why did you end up becoming a product design engineer? What inspires you? What are you most passionate about and proud of?

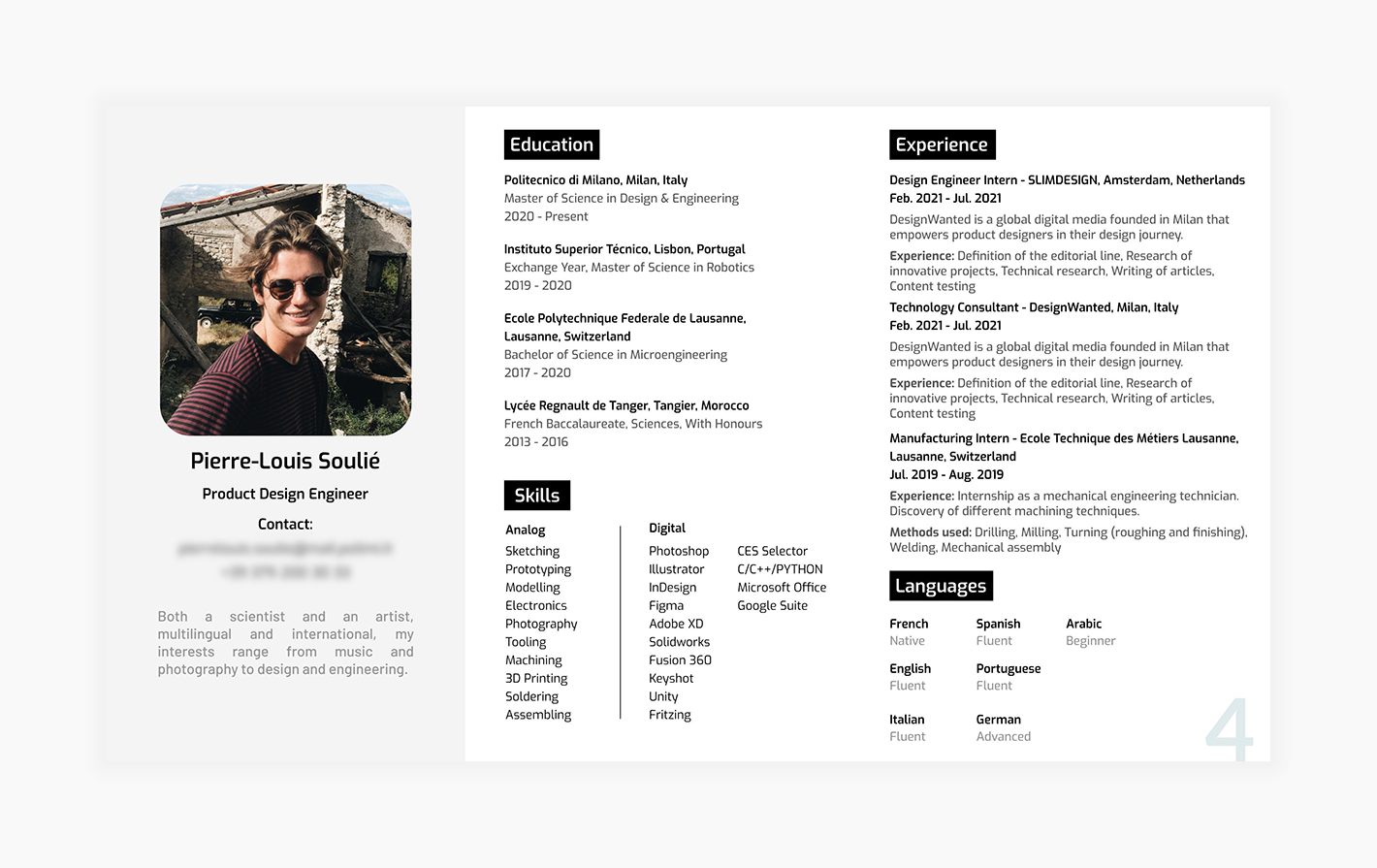

Resume section

The next structural element is basically a resume: lists of your work experiences, education, hard skills, soft skills, software proficiency, and accomplishments.

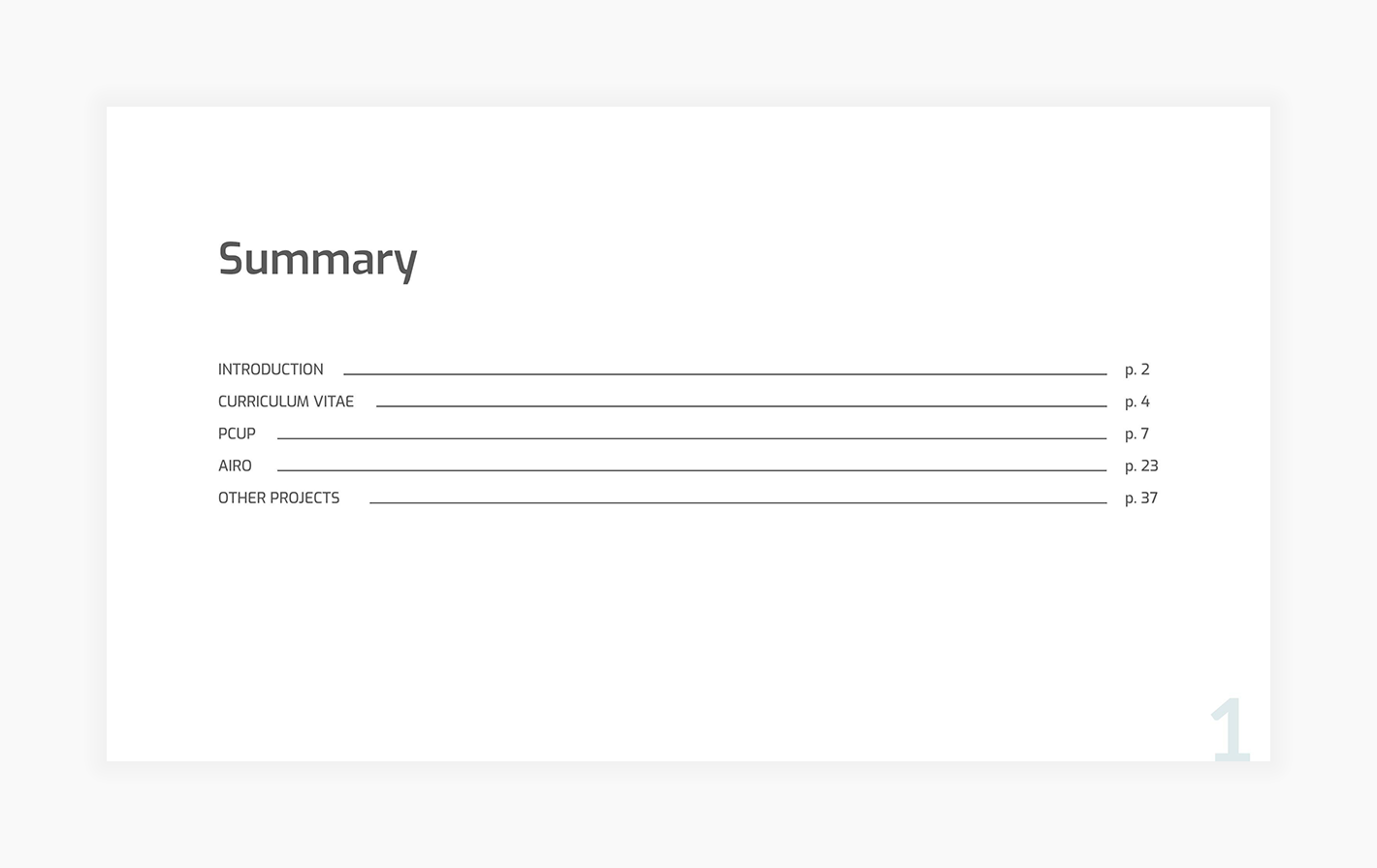

Index

After these general elements, most product design engineer portfolios continue with an index. It’s important to line up your projects strategically. Start with

- The project that’s the most relevant to the position at hand (uses the same/similar technologies, is from the same niche, etc.) or

- The project that best highlights your skills.

This is important because many recruiters won’t read the entire portfolio, they’ll just check the first projects before making a decision.

Projects

This is the part where you’ll showcase your work and skills. What’s similar in most portfolios is that they begin with a short description: what’s the product about, what are its mechanics, who is it intended for, and what were the objectives.

Then we get more details about the process alongside deliverables: 3D renderings, technical drawings, prototypes, design iterations, diagrams, and photos from various stages of the process. Make sure to add a caption to all of your images so your readers know exactly what are they looking at and why it’s important.

Many portfolios include school and challenge projects, so don’t worry if you don’t have any real-life projects yet.

Contact and thank you note

Most portfolios end with contact information and a short thank-you note for those who read the portfolio.

Product design engineer portfolio examples

Follow the links in the captions to see the portfolios:

What’s required of product design engineers at top tech companies: Apple, Google, Amazon

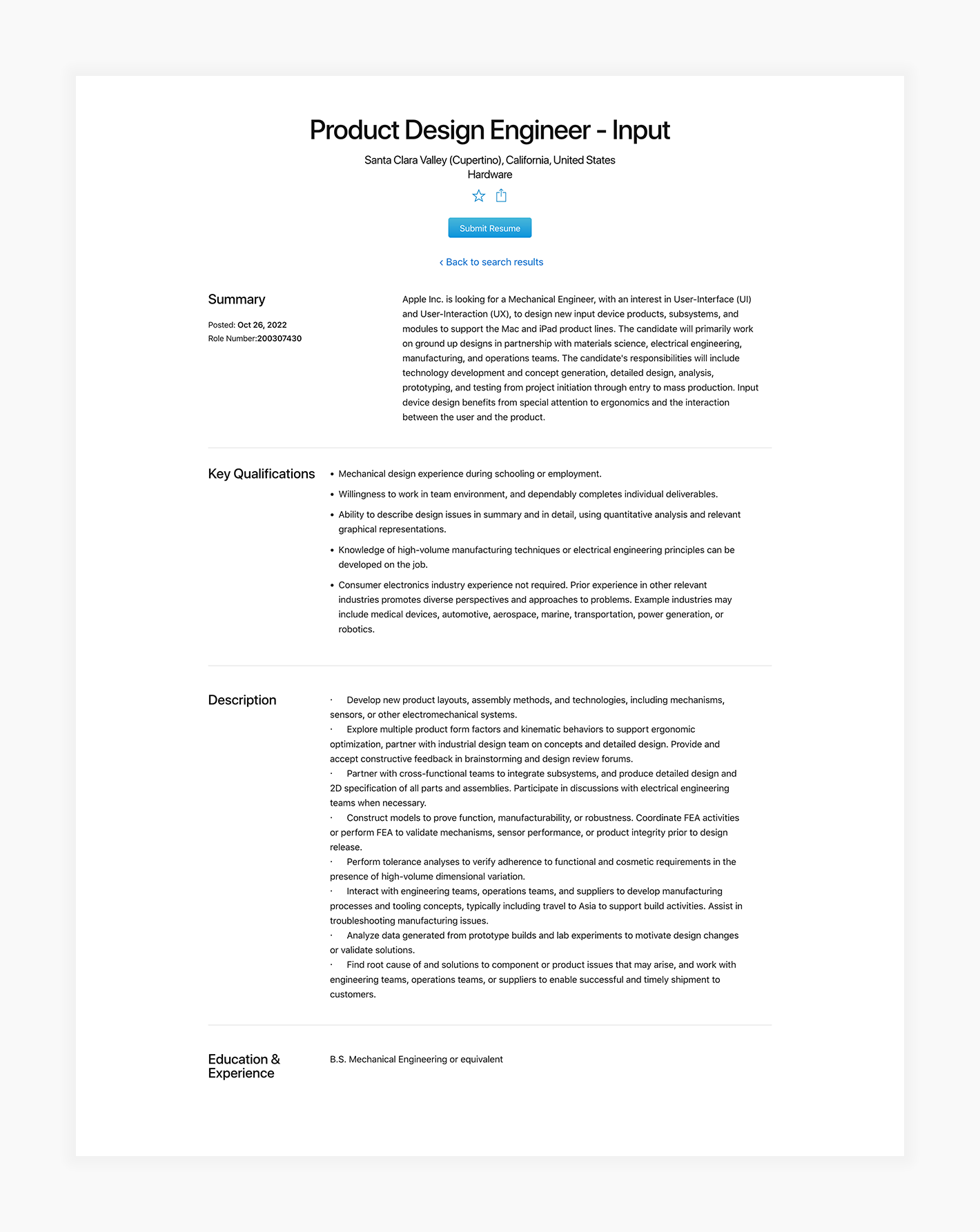

Apple:

Source: Apple

- Develop new product layouts, assembly methods, and technologies, including mechanisms, sensors, or other electromechanical systems.

- Explore multiple product form factors and kinematic behaviors to support ergonomic optimization, partner with industrial design team on concepts and detailed design. Provide and accept constructive feedback in brainstorming and design review forums.

- Partner with cross-functional teams to integrate subsystems, and produce detailed design and 2D specification of all parts and assemblies. Participate in discussions with electrical engineering teams when necessary.

- Construct models to prove function, manufacturability, or robustness. Coordinate FEA activities or perform FEA to validate mechanisms, sensor performance, or product integrity prior to design release.

- Perform tolerance analyses to verify adherence to functional and cosmetic requirements in the presence of high-volume dimensional variation.

- Interact with engineering teams, operations teams, and suppliers to develop manufacturing processes and tooling concepts, typically including travel to Asia to support build activities. Assist in troubleshooting manufacturing issues.

- Analyze data generated from prototype builds and lab experiments to motivate design changes or validate solutions.

- Find root cause of and solutions to component or product issues that may arise, and work with engineering teams, operations teams, or suppliers to enable successful and timely shipment to customers.

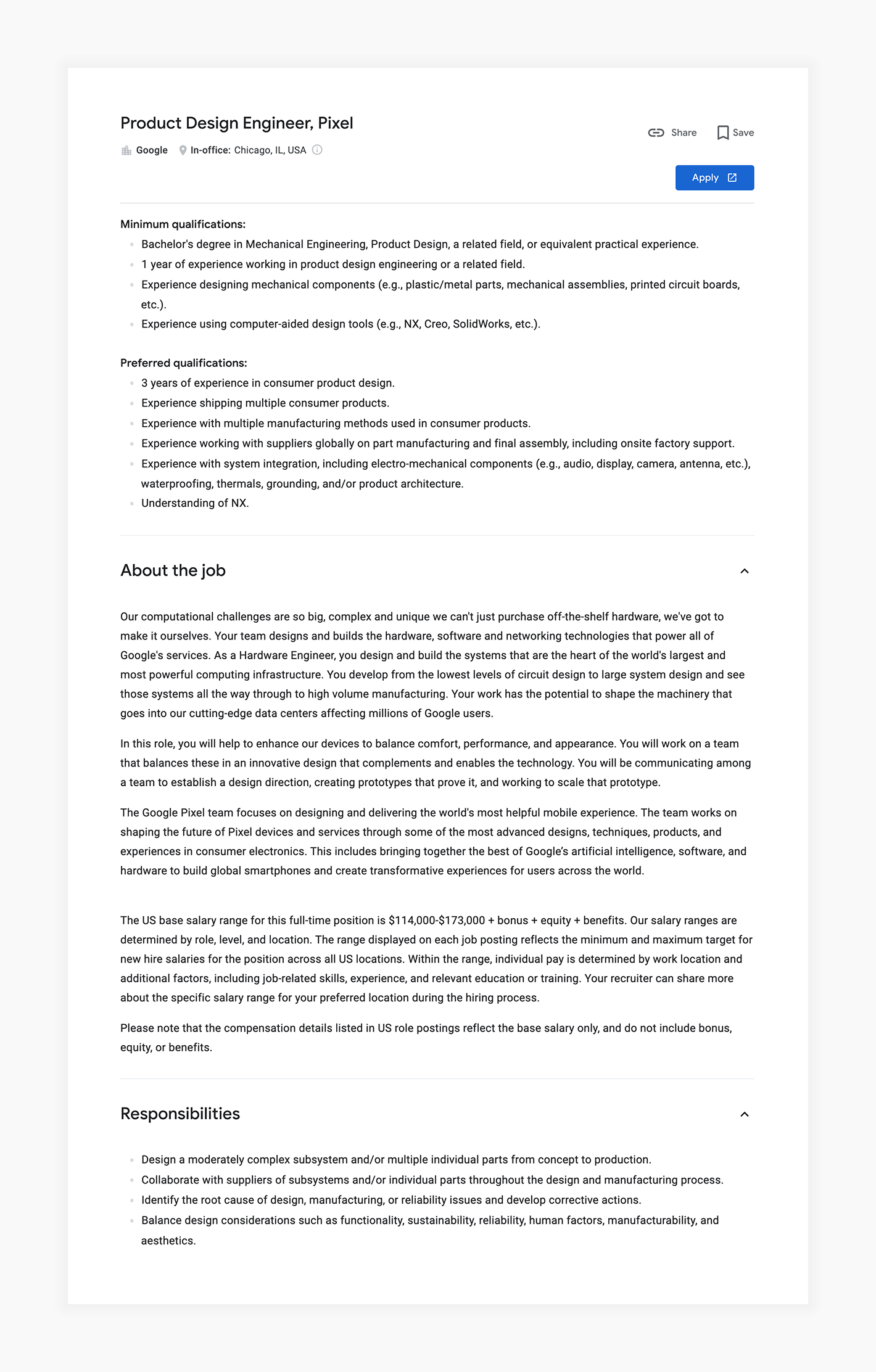

Google:

Source: Google

- Design a moderately complex subsystem and/or multiple individual parts from concept to production.

- Collaborate with suppliers of subsystems and/or individual parts throughout the design and manufacturing process.

- Identify the root cause of design, manufacturing, or reliability issues and develop corrective actions.

- Balance design considerations such as functionality, sustainability, reliability, human factors, manufacturability, and aesthetics.

Amazon:

Source: Amazon

- Design and build 3D models for testing, proof-of-concept, mock-ups, and functional appearance models.

- Find and interface with 3rd party suppliers and integrate their pieces into the whole system design.

- Support advanced R&D initiatives & prototyping efforts with team members of other disciplines.

- Participate in the cross-discipline design process for system design, combining your skills with HW and SW team members to arrive at integrated effective system designs.

- Work well with support resources to efficiently realize appropriate design portions.

- Identify emerging technologies to help define development opportunities.

- Research advanced materials and manufacturing processes.

- Anticipate and correct issues that may impact mass-production (DFx).

- Support positive team interactions to accomplish program objectives.

- Contribute to schedule & milestone commitments.

- Provide cross-functional program integration support.